Round Cooling Towers: DFC-50

Delta’s Series DFC-50 symbolizes round bottle-shaped FRP cooling towers. Our round bottle shape cooling towers embody excellent design, up-to-date technology and other innovative features.

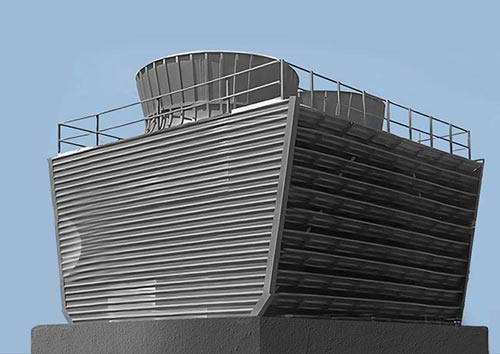

Square Cooling Towers: DFC-60

Our DFC-60 series cooling towers operate upon induced draft counter flow principle. These lightweight, tough, and compact cooling towers are modular in nature to help design a customized structure to suit the customer’s requirements.

CTI Certified Cooling Towers: DFC-60 UX

Delta’s DFC-60 UX series induced draft counter flow cooling tower is certified for thermal performance by Cooling Technology Institute (CTI) in accordance with CTI Standards STD-201.

Pultruded Cooling Towers: DPC-70

Delta’s DPC -70 series comprises Pultruded FRP Induced Draft cooling towers. These high-strength field erected Cooling Towers have excellent corrosion properties...

Pultruded FRP Cross flow Cooling towers: DPX-80

Delta’s DPX -80 series comprises Pultruded FRP Induced Draft Cross flow cooling towers. These high-strength field erected Cooling Towers have excellent corrosion properties...

Delta Device

Water passes through Delta device's special core causes more minerals to stay suspended in the water, so they cannot form a hard, brittle scale. Rock solid reliability of Delta Device