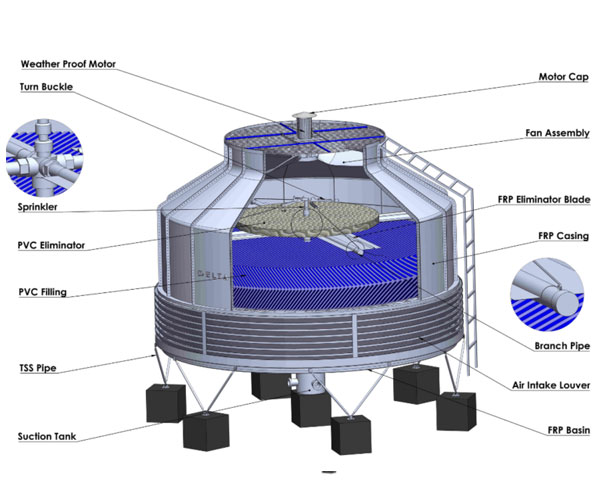

Our aesthetically designed DFC-50 series cooling towers comprise a bottle shape with an axial flow fan on the top to extend vertical air discharge. Industrial heated water flows into the cooling tower through water inlet connection provided in the auxiliary suction tank fitted underneath the FRP basin. The hot water, driven by the force of pump moves upward via center stand pipe fitted on to the auxiliary suction tank. A self-rotating sprinkler attached on the top of stand pipe rotates the water to distribute it evenly over the fills/packing.

The occurrence of counter interaction of air and water leads to the vaporization, which results in the thermal separation of heat. A small amount of water vaporizes to the atmosphere and the remaining water gets cooler. Finally, the cold water is collected into the leak proof FRP basing for re-circulating it to the industrial process.

The bottle shape facilitates in lowering the internal pressure drop of air. It also allows the external dry air to enter into the cooling tower from all directions. It is precisely because of this that the series reflects the most reliable and efficient cooling towers among all designs available in the market.